Furnace Industries is a small climbing-related business that specializes in ice-climbing training tools gear that can be used in gyms.

|

First let’s begin with some background history. How and when did Furnace Industries get its start?

Furnace Industries came from my UK-based business partner George Fisher. Over 2 years from 2011-2103 he and I developed the DRY ICE Tool with test users in US and UK gyms so that we could train more effectively but also safely indoors for ice and mixed climbing. With increasingly busy schedules, both he and I were looking for a solution to maximizing our time on the ice during the ever-shortening ice season. On January 1st 2013, Furnace Industries was officially born. It’s always great to put names and faces to a business. Who is behind Furnace Industries and who does what? George Fisher is the technical and design engine. I, Ben Carlson, am the business and marketing end. While George innovates new stuff, I have sought out other niche ice climbing products that I felt were missing from the world marketplace. I developed our new indoor ice climbing tool called the Evolution and also brought in Verticallife Drytooling Holds for use with real tools on artificial walls. Both of these new products fall directly in line with our product line of training gear and we are amped to be able to use our large market presence to be able to share them with the climbing world.” |

Are you both ice climbers? Do you also rock climb/free climb?

I always say that ice climbing is where it’s at, and I do truly believe that. But with the arrival of George’s second child and me with my first, our lives are wildly different than when we founded Furnace Industries. These days, George is able to hit the gym near Oxford UK a couple days a week, and I get out on my local cliff at the Gunks about once a week for a few rock sessions. When ice season arrives and conditions are right, I can sneak out for a morning romp on the ice in the Catskills north of NYC. When stars align, I can get up the Adirondacks of upstate New York for a day, and during ice fests I climb ice near Ouray Colorado, Silverton Colorado, and up in New Hampshire during the Mount Washington Ice Fest.

Are you both ice climbers? Do you also rock climb/free climb?

I always say that ice climbing is where it’s at, and I do truly believe that. But with the arrival of George’s second child and me with my first, our lives are wildly different than when we founded Furnace Industries. These days, George is able to hit the gym near Oxford UK a couple days a week, and I get out on my local cliff at the Gunks about once a week for a few rock sessions. When ice season arrives and conditions are right, I can sneak out for a morning romp on the ice in the Catskills north of NYC. When stars align, I can get up the Adirondacks of upstate New York for a day, and during ice fests I climb ice near Ouray Colorado, Silverton Colorado, and up in New Hampshire during the Mount Washington Ice Fest.

Where are you all based out of?

George lives with his wife and two children near Oxford UK in a small village called Hook Norton. I live about 90 miles north of New York City in New Paltz, NY with my wife and out 2 year-old daughter Paige.

Your training tools are really clever. Most of us have seen the training set-ups in gyms (and ice climbing competitions) that use some form of Styrofoam where the ice-axe is lodged in, but not many gyms have set-ups like that. Your “Dry Ice” tools have loops that wrap around holds and your “Evolutions” are more “hook-like.” Tell us about the evolution in the design of these tools and why you created these two different tool styles.

The Evolutions are the natural progression of the DRY ICE Tool, and we’re happy that in 2022, the market can finally sustain such a product. Attitudes have changed regarding training indoors for ice climbing. It’s clear the DRY ICE Tools had much to do with that change. Although we did develop something like the Evolution in the early days of Furnace Industries, the reason we did not go that direction in our final design of the DRY ICE Tool in 2012 was because it was clear that, at the time, gym owners and managers would not allow them. In our research, the moment we mentioned "ice climbing training" in a gym many managers flat out refused to continue the conversation due to perceived safety and liability concerns about sharp points flying about. Managers who listened closer however saw the potential for more customers and that’s how we got our foot in the door. Our pitch was: if you can offer terrain for folks to train for rock climbing, why not get more customers and offer routes for ice climbing?

The caveat, in 2012 at least, was that the tools had to “look” safe. They had to be look acceptable to the non-ice climber climbing next to you at the gym. Our very similar early version of the Evolution was perceived of as too dangerous to use with other climbers around in a gym setting. The DRY ICE Tool idea was much more agreeable to folks, so we when that direction.

The Evolution delivers where the DRY ICE Tool leaves you wanting more. Its design solves many of the shortcomings of the the DRY ICE Tool. You’ll notice they are a bit more expensive. This is due to the material cost and engineering that goes into producing them. They are essentially real ice tools, metal skeletons sheathed in wood to provide a large enough pad for the sticky rubber tip to friction on small edges in the gym. The Evolution is a massive leap forward and we’re happy integrate them into our DRY ICE line of tools and holds.

The caveat, in 2012 at least, was that the tools had to “look” safe. They had to be look acceptable to the non-ice climber climbing next to you at the gym. Our very similar early version of the Evolution was perceived of as too dangerous to use with other climbers around in a gym setting. The DRY ICE Tool idea was much more agreeable to folks, so we when that direction.

The Evolution delivers where the DRY ICE Tool leaves you wanting more. Its design solves many of the shortcomings of the the DRY ICE Tool. You’ll notice they are a bit more expensive. This is due to the material cost and engineering that goes into producing them. They are essentially real ice tools, metal skeletons sheathed in wood to provide a large enough pad for the sticky rubber tip to friction on small edges in the gym. The Evolution is a massive leap forward and we’re happy integrate them into our DRY ICE line of tools and holds.

|

You also have a smaller version your tools called “Icicles.” What the idea behind those?

The plan for ICICLES® was simply to make a kid-sized tool. Many ice climbing parents asked us for them so they could share ice climbing with their children but in a kid-friendly gym setting. If you look at the ice climbing market, there is not one ice climbing axe designed for a kid. Our plan was to offer a training tool so kids could have fun and try the movement in the gym, and then when they are older, they are more ready to get into climbing ice. |

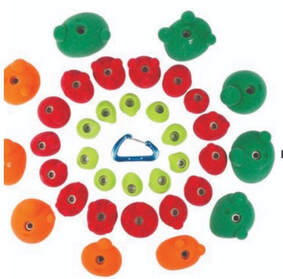

With COVID home gyms are becoming more commonplace. You also sell “holds” that are designed for a metal ice pick. You have metal holds and plastic holds. How are these hold types intended to be used?

Our line of climbing holds from Atomik Climbing Holds are designed to be use specifically with DRY ICE Tools. Recently we started offering Verticallife Drytooling Holds to be used only with real ice tools. With the explosion of home gyms, we felt offering drytooling holds would better serve the market well since many ice climbers with home gyms aren’t that bothered with some minor nicks in their climbing wall. Our DRY ICE Holds for our DRY ICE Tools are intended for gym use and also for the home user who doesn’t want to deal with damage to their home wall.

Are you seeing these ice climbing holds going into home gyms, or is your market for these mostly commercial gyms?

Mainly home gyms. Our DRY ICE Tools work with many holds, not just our specific line from Atomik, so commercial gyms usually have holds that will work. Home gyms owners, however, find our holds fill the gap in their hold selection, so they tend to be our primary market for holds, turning their walls into ‘ice’ climbs.

The COVID pandemic has been challenging for many climbing-related businesses. How is Furnace Industries managing the pandemic?

We’ve always been a small outfit where George and I still build all the tools by hand. While George and I would love for Furnace Industries to be our full-time jobs, alas, ice climbing is still pretty small. Growing, but still small.

George continues to be busy with his work as an in-demand bespoke wood worker, but my career as a lighting designer for concerts and live events has been devastated. For me, Furnace Industries has been able to fill a void where my other work has evaporated. I’ve taken that time to bring some new products on board, as well as figure out some streamlining of our business practices like bookkeeping, taxes, advertising, scheduling product shoots, and other really boring stuff that goes into running a climbing gear company. I’ve also been working on a new website for Furnace Industries.

Where and how are your tools made?

DRY ICE Tools and ICICLES are cut in batches on a CNC (computer numerical control) machine at a commercial shop. The parts are then delivered to George in the UK and myself in the US and we proceed to sand them till they’re just right, insert the custom bushing for the straps, brand the logos on with a heated branding iron (cue the puff of smoke, because there really is one), attached the die cut straps that we produce ourselves, package them up and, boom, out they go to our retailers and directly to our customers via our site.

|

How did you come up with the name Furnace Industries? Since the idea for the tool was George’s, I deferred to him for the name. When he was a small boy, he imagined one day of owning a company called Furnace Industries since his boy-child liked the idea of forging things, producing assembling them into titanic machines that did massive things. He even had a pencil as a kid that he labeled "furnace industries" that he has kept with him for his whole life. Who am I to deny a man his life-long dream of forging things that change the world, in this case, strong climbers? What is it like owning a small business in the climbing world? What advice would you give to anyone considering it? Don’t believe the haters. In the almost 10 years that George and I have been selling DRY ICE Tools and other creative training solutions we have seen all manner of naysaying and negativity for our ideas. The internet is a brutal, heartless, demolition derby of hate and mockery. It’s easy to read the comments and want pack up the whole operation. But both George and I love climbing ice, and while neither of us may be putting up major first ascent in far off ranges, Furnace Industries is our way of giving back to a climbing community that have given us so much. |

In fact, I know we’re helping climbers get stronger as a few new routes have been climbed by users of our products. The winner of the 2019 Ouray Ice Festival Eleite Climbing Competition, Marianne Van Der Steen, is a DRY ICE Tool user, and that feels good get that kind of validation.

Any last words for our Common Climber readers?

Stay strong, train hard, and remember #ItsAlwaysIceSeason!

Stay strong, train hard, and remember #ItsAlwaysIceSeason!

Check out Furnace Industries at:

- Website: https://furnace-industries.com/

- Facebook & Instagram: @furnaceindustries

- Amazon