Common Climber Marketplace highlights small climbing-related businesses to help spread the word about their work and to help our community thrive.

Lacaida Ropes is a brand new rope company based in Arkansas. It is established by Pedro Somarriba who is a veteran and climber. The name Lacaida is based on the Spanish word La caída which means "the fall" in Spanish. This interview is part of Common Climber's small business Marketplace where we connect you with the owners and creators of climbing-related small businesses.

Pedro, thank you for taking the time to share your story with us. Let's begin with your background. Can you fill us in?

|

Both of my parents relocated from Nicaragua during the Sandinista uprising in the 1970’s. They settled in Atlanta, where I was born. We moved around, living in Savanna, Miami, Sau Paulo, and Mexico City, eventually settling in Weston, Florida. I went to the University of Florida for undergrad and served six years in Army Special Forces, mostly in Okinawa, Japan. Separating from the service in 2016, I earned an MBA at Duke University.

My wife Emily and our then-two daughters moved to northwest Arkansas in 2018 so I could take a finance job at Walmart. I promoted to a Buyer role in 2019, buying plumbing and garage storage items. I learned how to launch a brand, designing Walmart’s first line of bidets just prior to the 2020 toilet paper shortage. During the Army and grad school years, I didn’t get to climb much. Settling down in northwest Arkansas was a welcome change of pace. I had the time to really get into the sport and later, the community. 2019 saw me and my climbing partner Bailey Whitaker survive the 12-hour Horseshoe Hell competition. By 2021 I followed him up Ancient Art in Moab and together we suffered the full 24-hour Horseshoe Hell. |

Why ropes and why your own business?

|

It started as a side-hustle. I wanted to work for myself in a field I was passionate about. I started selling on Amazon; a 10.5mm, unremarkable rope - it did not sell well. That got me thinking about how I could set my product apart through innovation.

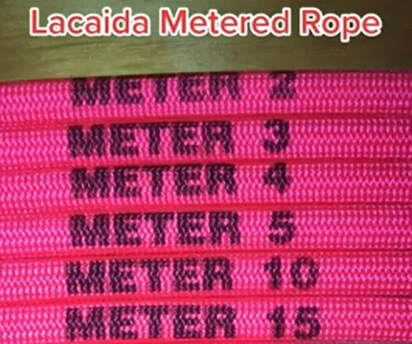

At Horseshoe Hell last year, I had picked up a bunch of free old climbing magazines that someone was giving away. I was flipping through pictures from the late 90’s and 2000’s and I noticed: rope hadn’t changed much. I Googled some pictures of climbers in the 70’s and 80’s and confirmed that despite innovations in supersonic/heat-sealed ends, dry-treatment, connecting sheath-core, and vinyl labeling, the rope still mostly looked the same. That gave me an idea - could I use vinyl labels to add cool patterns and make the rope more aesthetically pleasing, customized, or safer by marking the mipoint and meters. Well, I was lucky enough to have mentors who helped me see the obvious: rope is a life-saving product. If I am going to innovate, I should focus on making the rope safer. We shelved aesthetics and customization for now (though we hope to one day pivot back to that) and focused on safety. Enter the Metered Rope. I shared the idea with fellow climbers and got a lot of positive feedback. They helped me figure out which markings to make and how to orient the font. They told me what they valued in their rope. Those conversations also got me thinking about other innovations I could make in rope, but we’ll save those for later this year. |

What are your goals and vision for your company?

|

We want to make the safest, prettiest, and most useful climbing rope in the world, period.

We want to represent our home state. Arkansas has such a strong and active climbing community. Every day someone is out in the Ozarks or Ouachita, discovering a new crag, putting up an FA, or bolting a new route. Per Mountain Project, our state has about 2,600 routes. I think that may be just 10-15% of what’s out there. I believe climbing is for everybody. At Lacaida, we strive to be inclusive in how we market our products and who we choose to collaborate with. We want to be a platform to women, LGBTQ, BIPOC, paraclimbers, and other underrepresented groups of climbers. We want young people to see themselves in our sport, and develop into the next generation of recreational, amateur, and professional climbing leaders. Strategically, we plan to focus sales through local outfitters and national festivals. From there, we intend to expand into regional and national franchise retail and wholesale. |

You said you are in the process of patenting some elements of your ropes. Are you able to elaborate upon that? What is it that you are patenting?

Metered Rope (TM and Patent pending) 😊

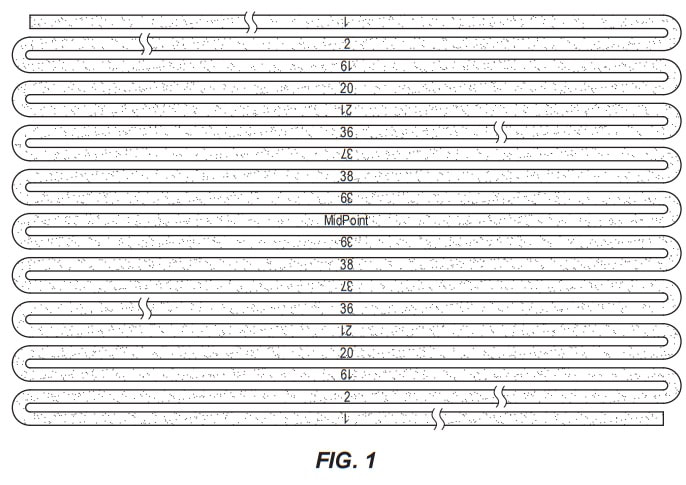

We mark the midpoint like many other ropes, and then we mark the meters. Starting at the midpoint, we mark each meter counting down towards the rope ends. Once we arrive at the 5th meter in either direction, the markings become less frequent, just every 5 meters. As we get to the 5th meter from the rope ends we revert back to counting each meter.

We think this helps climbers in several ways. First, it takes the guess work out of FA’s and every day lead climbing. There’s no reason to run out of rope as the lead when your belayer can tell you exactly how much rope you have left. Second, the higher frequency of markings signals to the climber they’re approaching the rope ends or the midpoint, simplifying multipitch climbing and adding another layer of safety when rappelling. Finally, it couldn’t be easier to cut off rope ends – just cut one meter off each end and that’ll keep your midpoint the same.

Here’s an image of the patent filing that conveys the overall design using a 40m rope as an example:

We mark the midpoint like many other ropes, and then we mark the meters. Starting at the midpoint, we mark each meter counting down towards the rope ends. Once we arrive at the 5th meter in either direction, the markings become less frequent, just every 5 meters. As we get to the 5th meter from the rope ends we revert back to counting each meter.

We think this helps climbers in several ways. First, it takes the guess work out of FA’s and every day lead climbing. There’s no reason to run out of rope as the lead when your belayer can tell you exactly how much rope you have left. Second, the higher frequency of markings signals to the climber they’re approaching the rope ends or the midpoint, simplifying multipitch climbing and adding another layer of safety when rappelling. Finally, it couldn’t be easier to cut off rope ends – just cut one meter off each end and that’ll keep your midpoint the same.

Here’s an image of the patent filing that conveys the overall design using a 40m rope as an example:

Tell us about the line of ropes you will have.

|

We will have two ropes to start with. The Fitzgerald is our lower priced model. Built for heavy-use, it features a dry-treated core, baby blue color and thicker weave pattern on the sheath. With a 9.9mm diameter it is ideal for gym use and performs well outdoors. It was named after Fitzgerald Mountain, a local climbing spot, just a 5-minute drive from my house.

The Lincoln is our higher end model. With a sleek, tighter weave on the sheath, dry-treated core and sheath, and hot pink color, it stands out in a crowded market before we even apply the markings. We often hear climbers guess that the Lincoln is a 9.3 or 9.4mm because the sheath weave is so smooth. It’s actually a 9.9mm. We named it after Lincoln Lake, another local crag. |

There are quite a few companies that make climbing ropes. The Metered Rope certainly sets you apart. Anything else?

Besides the markings, we have some other ideas. These other designs will advance climbing even further than Metered Rope, with additional safety features for sending in all kinds of environments. We are also experimenting with different kinds of markings, rope sizes, and sheath colors. We’ve received a fair amount of interest from other climbers like arborists, safety workers, first responders, freedivers and cave divers. Each of those communities has their own preferences, like using feet instead of meters, or one-directional markings.

We’re not stopping at the dynamic rope either. We plan to launch a line of climbing static ropes this Fall.

We’re not stopping at the dynamic rope either. We plan to launch a line of climbing static ropes this Fall.

|

Many people defer to the big-name companies because there is a sense of safety in that. Can you explain for our readers how you know your ropes are safe?

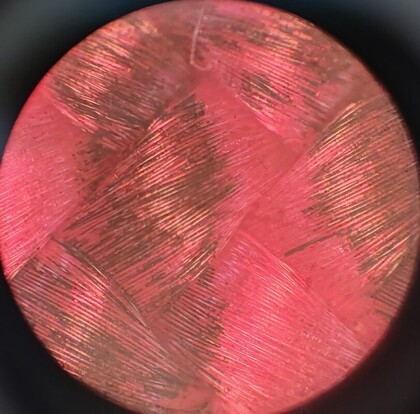

Our ropes are UIAA certified, twice: first when they are made, and again after they are marked. We put the individual fibers of the marked rope under a microscope and compared them to the unmarked fibers. We then checked on them after certain time intervals, with and without UV exposure. Then we performed the same test again so we could test different types of ink. I think that rigorous additional testing process manifests the “over and above” approach we take to safety.

Both of our first two ropes are dry-treated, with the pink-colored Lincoln model being UIAA dry-certified. We believe Metered Rope is the new standard in safe climbing. Given two ropes of equal quality and strength, it is safer to climb with a Metered Rope than a blank or midpoint-only marked rope. Our early adopters know that as soon as they hear about our rope. I guess with a metered rope there is no need for a bi-pattern or bi-color rope?

Bi-pattern no need because you have no question where the mid-point is. Bi-color maybe.

To a man with a hammer everything looks like a nail. And to incumbent rope manufacturers with millions invested in braiding/spooling/dyeing/autoclave machines, every innovation starts and ends with braiding and/or dyes. |

Don’t get me wrong, bi-patterns/bi-color ropes were a great first step towards permanently marking the midpoints. I also love what Trango did with their Agility rope, using a different color as you approach the rope ends. But, air splicing (fusing individual nylon fibers under high air pressure) is very expensive, and so are those ropes. That is because they are labor intensive products. Think about the cost to have someone stop the braiding process to switch out bobbin colors, air splice each individual fiber, and then restart the braiding machine. On every rope. Sometimes twice per rope.

Our technology achieves the same end (no pun intended) at a fraction of that cost, and with the added benefit of more informative markings. We have a healthy respect for other rope makers, many of whom inspired us. But why spend $400 on a bi-pattern or bi-color rope when ours costs $70 less and provides far more value? Metered Rope is the new standard. Period.

In theory, a Metered Rope could be bi-color. If the common climber wants that, we will absolutely try that in the future (DM me on Instagram). In fact, if there are any climbers out there reading this who have used bi-color ropes for the past few years, we would love to hear from you. [email protected] or DM @lacaidaropes on Meta platforms.

Our technology achieves the same end (no pun intended) at a fraction of that cost, and with the added benefit of more informative markings. We have a healthy respect for other rope makers, many of whom inspired us. But why spend $400 on a bi-pattern or bi-color rope when ours costs $70 less and provides far more value? Metered Rope is the new standard. Period.

In theory, a Metered Rope could be bi-color. If the common climber wants that, we will absolutely try that in the future (DM me on Instagram). In fact, if there are any climbers out there reading this who have used bi-color ropes for the past few years, we would love to hear from you. [email protected] or DM @lacaidaropes on Meta platforms.

How long do the markings on your Metered Ropes last?

|

While we think the marks were engineered to be permanent, only time will tell if that's true. The ink and marking technology we use is fairly advanced. It was made to permanently mark a wide variety of materials such as metal pipes, ceramic tiles, glass, apparel, and cardboard boxes.

I have two ropes out in the field with our sponsored climbers. As of now, they've been climbing on those ropes for a month, and I have been meeting with them to find out how the rope markings are holding up. I think it's important to note that our ropes hold the ink better than other ropes. For instance, the Lincoln has an uncommonly tight weave pattern and uses only one type of nylon fiber. This is important because it inhibits "fuzzing" on the rope, wherein individual fibers on the sheath tear and stick straight up, forming a cloud of fuzz. That fuzz would make any markings illegible. Ropes with mixed-material fibers and looser sheath weaves seem to fuzz more easily. |

Where will your ropes be made?

As of this writing we are located at the Loloft industrial-coworking space in Rogers, Arkansas. Come visit us!

It seems like there would need to be a lot set up ahead of time for manufacturing. What is that process like?

You ain’t lying. First, you would need to find a commercial warehouse and sign a yearly lease to pay $2k per month. You’ll want to spend at least several hundred thousand dollars to buy up all those machines I mentioned earlier, and a couple thousand on the proper certifications (ISO, etc.). Next, spend tens of thousands on your raw materials like dyes, waterproofing agents, nylon fibers, spools, packaging… the list goes on. Finally, you would need to spend $1-1.5k on certification testing for each rope design you produce.

While we still incur the testing costs, marking costs, and have bought some expensive machinery to improve the finishing features of our product, we were able to circumvent most of the major expenses by simply contract manufacturing and using a shared workspace. We worked with local companies everywhere we could, and choose the most sustainable option wherever possible. For instance, choosing paper over plastic packaging.

It seems like there would need to be a lot set up ahead of time for manufacturing. What is that process like?

You ain’t lying. First, you would need to find a commercial warehouse and sign a yearly lease to pay $2k per month. You’ll want to spend at least several hundred thousand dollars to buy up all those machines I mentioned earlier, and a couple thousand on the proper certifications (ISO, etc.). Next, spend tens of thousands on your raw materials like dyes, waterproofing agents, nylon fibers, spools, packaging… the list goes on. Finally, you would need to spend $1-1.5k on certification testing for each rope design you produce.

While we still incur the testing costs, marking costs, and have bought some expensive machinery to improve the finishing features of our product, we were able to circumvent most of the major expenses by simply contract manufacturing and using a shared workspace. We worked with local companies everywhere we could, and choose the most sustainable option wherever possible. For instance, choosing paper over plastic packaging.

When do you anticipate the first ropes to be released?

I anticipate the first ropes will be released for sale in June of this year. It would be fantastic if we could launch at a climbing event or festival in June. For now, the exact date is TBD.

Have you run your own business before? Who else is on your team?

|

Yes. While not strictly “my business” I did run 12 categories of products at Walmart totaling close to $2 Billion in annual sales. I also developed a brand from scratch, the Rinslet line of bidets I alluded to earlier.

I run a small real estate business for myself. That business started with a monthly rental. A 3 bed/2 bath remodeled house in Jasper, AR, just 15 minutes from Horseshoe Canyon Ranch. While this is my first foray into the rock climbing, it won’t be the last. Once Bailey and I complete the SPI course and pass the exam, we intend to launch a rock-climbing guide service in Northwest Arkansas focused on serving people who haven’t climbed outside before or who may never have climb before. Lacaida does not have any formal employees yet. That said, Lacaida wouldn’t have gone anywhere without the generous support of family, friends, countless local business owners and crushers, business mentors, and Lacaida’s suppliers. Shout outs to my wife Emily who found the inspiration for our marking process; my friend Chris Hillyer for helping me think through my initial designs; Phil Shellhammer and the Greenhouse Outdoor Rec Program (GORP) for getting us off to a running start via their incubator program; Lacaida-sponsored athletes Andrea Maillard, Lane Alexander, Chris Royer and Uli Garcia, and brand ambassador Zachary Childers, all of whom were the first to tie into a Lacaida Metered Rope. |

Find Lacaida Ropes:

WEBSITE: https://lacaidaropes.com/

INSTAGRAM: @lacaidaropes

FACEBOOK: @lacaidaropes

CONTACT: [email protected] or DM @lacaidaropes on Meta platforms

WEBSITE: https://lacaidaropes.com/

INSTAGRAM: @lacaidaropes

FACEBOOK: @lacaidaropes

CONTACT: [email protected] or DM @lacaidaropes on Meta platforms